Home | Full Mods List | Pictures | Videos | Achievements | Contact Me

Home |

Full Mods List

| Pictures | Videos | Achievements

| Contact

Me

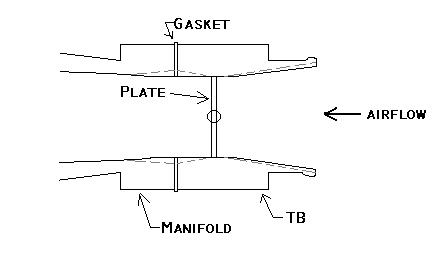

This is basically what I ported. It's a rough drawing, but it gives you the idea.

Note: Please read these

instructions in there entirety before attempting to proceed. This 'write up' is

only for information purposes only. I am not responsible for anything that you

mess up.

Since I get 5 questions per day on intake port work, I thought I'd do a write up

on my thoughts on port work on a VE30DE.

First, I highly recommend you buying a Deluxe Porting Kit from

www.summitracing.com .

Standard Abrasives makes the best porting kit. But a cheaper one can be gotten

by just buying the summit brand kit. I think it's $30-40 for the kit with ALL

the bits you'll ever need for every porting project. I LOVE those sandpaper

cartridge rolls that are shaped like a cone. It looks like a cone shaped roll of

toilet paper, except that it's sand paper and not soft toilet paper. Don't get

the two confused or you might be finding out what a proctologist does for a

living. These bits work better than any other bits I've ever tried. And I've

tried them all.

------------------

Here are some kits on SummitRacing.com that I think would be perfect for this

project:

Standard Abrasives Port Kit SAI-260001 $39.88 (The kit I used and i think the

best kit you can buy)

Standard Abrasives make other port kits, but I don't know what bits they come

with so I can't recommend them:

SAI-260007

SAI-260012

Summit Racing Porting and Polishing Kit SUM-G1060 $28.39 (It looks like this kit

will work just fine but it doesn't come with a polishing bit)

-------------------

Next, you'll need a die grinder or electric rotary grinder that uses 1/4" shank

bits. A really high speed drill might work ok. But try to atleast have something

that's able to spin at 15,000 rpm or more. I have a rotary grinder that spins

that 30K rpm, which is too much for some port work. I would recommend a variable

speed electric rotary grinder or variable speed air powered die grinder. I

HIGHLY recommend that you stay away from Dremel tool 1/8" shanks. Those small

shank bits break WAY too easy and you'll go through $50 in bits and a lot of

headaches just to do a very crappy port job.

From my pics, I'm sure you can see how to port. I highly recommend having a

spare TB. A spare upper intake might help just in case, but there's nothing that

can really go wrong with matching the intake port opening.

About the TB (throttle body), I got a bench vise, tightened it down so the TB is

sitting at an angle that you can work with. Then start going to town on that

thing. Don't bare down too much, just take it slow and work your way towards the

TB plate. DO NOT touch anything part where the TB plate seals. Just keep the

plate closed at all times and port up to the plate. Expect to take atleast 5

hours to do a NICE port job. Then you can attach the polishing bit that comes in

the kit and polish that TB to a mirror finish. :) Flip the TB over and do the

backside of it. You won't port nearly as much metal as you just did on the front

side.

The stock backside of the TB should be 61mm. I think I ported mine to 63mm. As

for the front, I'm not sure what the before and after measurements were, but the

TB opening was pretty sharp. :) Just port as much metal as you safely can

without poking throught the TB wall.

Now, you have to match the intake manifold to what you just ported. Stuff lots

of lent free shop towels in the intake manifold while it's still on the car.

Stuff some more for safe measure. Make sure you stuff enough that no metal dust

can get past the towels. I used blue paper shop towels. Take a measurement of

the backside of the TB with a vernier caliper or a ruler, I guess. :) Then mark

with a sharp pen or pencil on the upper intake manifold (IM) so you know how

much to port. Then start matching it. This part of the process should only take

about 30 minutes to port. It's pretty simple since you don't have to remove much

metal. You might have to trim the stock TB gasket a little to get it to fit in

the new port.

Now after you think you have gotten close, get two TB bolts and hook up the TB

securely so it doesn't flop around. Open the TB plate and feel in there with

your finger and see where there is a lip. There should be a lip all around, so

remove the TB and port some more in those areas.

It's not a good idea to port too much from the IM b/c that would create a little

dip (or cliff) that the air has to flow over and it might swirl the air in a

fashion that's not good for performance. You want the TB to IM transistion to be

as perfect as possible. No upward or downward lip.

After you have the IM matched to your freshly ported TB, get a shop vacuum and

suck out as much metal dust as you can before you try removing the paper towels.

Clean it up really nice and then slowly remove the paper towels and then inspect

the IM for more metal dust. Suck it all out and wipe the inside clean. A little

metal dust won't hurt, but as picky as I am, I made sure it was perfectly clean.

Home | Full Mods List | Pictures | Videos | Achievements | Contact Me

Copyright © 2005 by Innovative Web

Design.

All rights reserved.

For comments or problems with this site, please contact Webmaster

Updated on 9/15/05